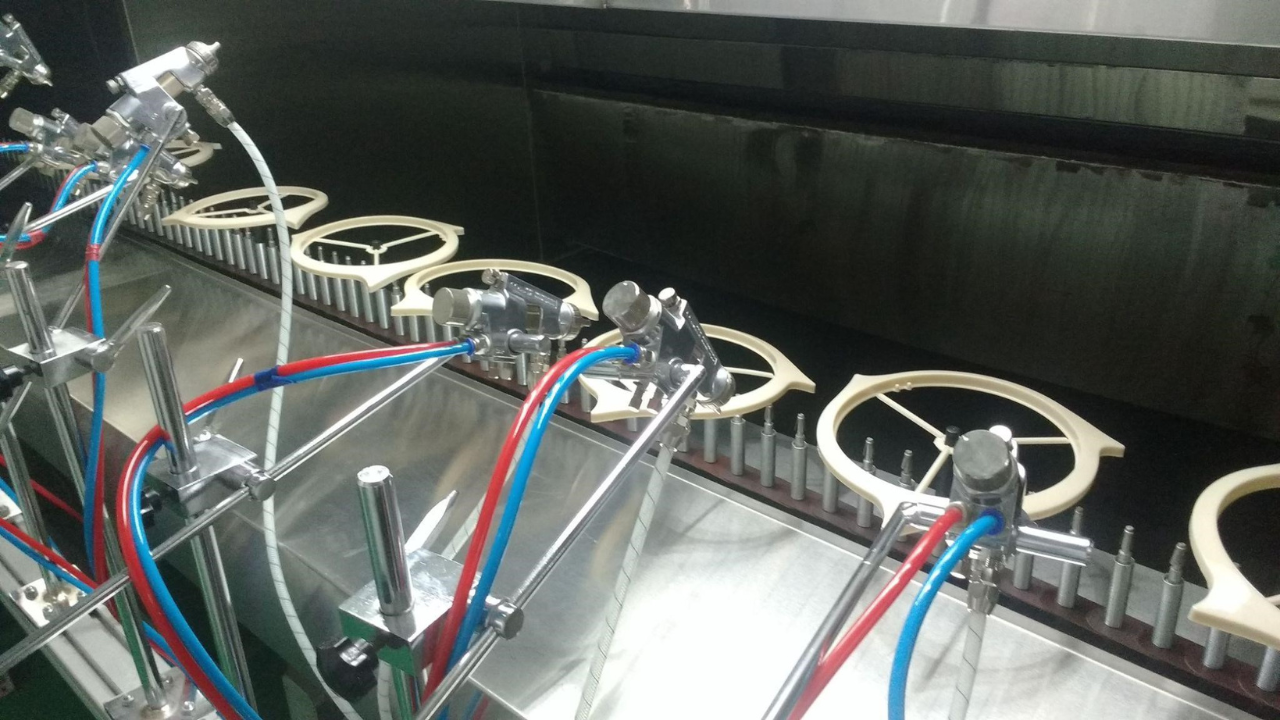

UV Curing Plant

UV Curing Plant

SGSP UV Curing plant line is designed to operate highly efficiently and reliably for many years and customized for each project. Ultraviolet curing (commonly known as UV curing) is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings or adhesives.

UV formulations are liquid monomers and oligomers mixed with a small percent of photo initiators and then exposed to UV energy. In a few seconds, the formulation - inks, coatings or adhesives instantly “harden” or cure, ready for the next processing step.

SGSP UV Curing plant take care of everything from design and manufacturing to installation and commissioning.

SGPS Customized UV curing plant meets clients’ requirements for;

Glass - Glass and ceramic decorators using UV curing gain the advantages that plastic decorators enjoy: the ability to directly print multiple colours at high speed, in any colour, free of heavy metals, using quick, simple, low-cost curing. UV-curable inks are commonly used to decorate and mark a variety of glass products including beverage bottles, drinkware, mirrors and flat glass, packaging for cosmetics, perfume and personal care products

Plastic- Electronic devices, modern cars and computers contain many components made of plastics. Gear levers, keyboards, key panels and decorative components are printed, coated with a transparent varnish or a coloured base coat to achieve a perfect surface. Depending on the process and the plastic coating, what you need for drying is a heat solution, a UV solution or a combination of both technologies.

Metal - Manufacturers of metal cans, pipe, and other products use UV curing for decorating, protecting parts and improving production rates dramatically. UV curing on metal substrates is now common for applications such as decoration and functional coatings on beverage cans, protective coatings for pipe and tube and nameplate/identification tag decorating. In addition, a wide variety of coatings on metal parts from propane tanks to under hood automotive parts, oil filter housings and motor assemblies are UV cured.

Paper - Coated papers are nothing new. They are used often for business cards, marketing materials and other products that need a bit more longevity and that need to look good. The right coating can make your paper product stand out. However, some coating options just won’t work for paper while others are harmful to the environment. The best option is UV coating for paper and same can be done by UV cured.